Top Quality MGO Board for External Wall Panel

Overview Product Description Magnesium Oxide board is a fire resistant building material made from naturally occurring m

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | MW01 |

| Type | Magnesium Oxide Board |

| Edge | Square/T&G/Tapered/Beveled |

| Shape | Rectangle |

| Usage | Building |

| Moisture Content | Less Than or Equal to 8% |

| Impact Strength | 3.5 Kj/M2/Custom |

| Wet Expansion Rate | Less Than or Equal to 0.3% |

| Chloride Ion Content | 0.1%(MOS), 3%(Moc) |

| Shrinkage | Less Than or Equal to 0.3% |

| Density | 0.8-1.35kg/M3/Custom |

| Flexural Strength | 8-25 MPa |

| Fire Performance | No Burning, No Black Smoke, No Poisonous Gas |

| Customization | Available |

| Transport Package | Pallet or in Bulk |

| Specification | 4*8ft, 4*9ft, 4*10ft |

| Origin | China, Shandong |

| Production Capacity | 500000 Pieces Per Year |

Product Description

Magnesium Oxide board is a fire resistant building material made from naturally occurring minerals: magnesium oxide and magnesium chloride/sulfate with various fillers to provide a range of material properties.MgO Board is particularly useful where fire protection is essential and for assemblies rated against damage by water, sound, impact and mold. MgO boards are a superior replacement for all gypsum and fiber cement wallboard, can also be used structurally to replace fire resistant OSB or plywood sheathing.

Application-External cladding-Roof lining and installation-Bathroom linings-Flooring sheathing-Internal wall sheathing-Acoustic requirements-Fire separation wall systems-Suspended & acoustic ceilings-Skin of SIP panels-Furniture manufacturing

| Main materials | MgO, MgCl2/MgSO4 |

| Fire performance | No burning, no black smoke, no poisonous gas |

| density | 0.8-1.35kg/m3,custom |

| Flexural strength | 8-25Mpa |

| Impact strength | ≥3.5 kJ/m2,custom |

| Moisture content | ≤8% |

| shrinkage | ≤0.3% |

| Wet Expansion Rate | ≤0.3% |

| Nail holding rate | 40-100/(N/mm)CUSTOM |

| Chloride ion content | 0.1%(MOS),3%(MOC) |

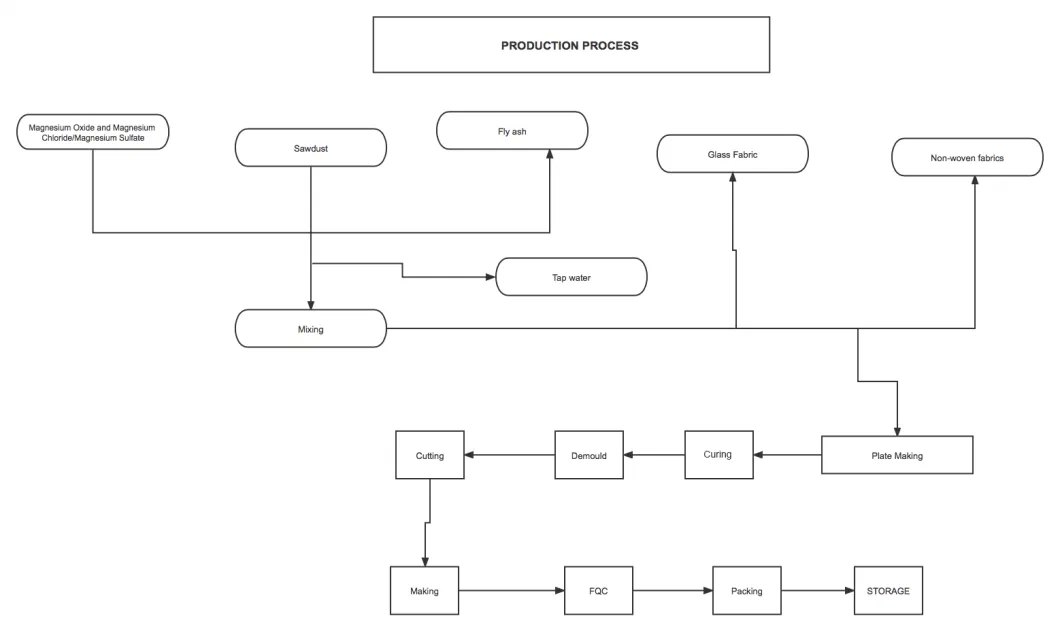

MgO boards are made of Magnesium oxide(MGO), magnesium chloride/sulfate, perlite, wood sawdust, fiberglass mesh, non-woven cloth etc. Like other cement products, it takes 4 weeks for MgO boards to get fully cured. Our production facility has metered raw material silos, monitored curing chambers to ensure the right molar ratio and curing condition during production. We have very good relationship with CMMA experts to assist with formulae and QA. Our MgO boards are produced according to Chinese National MgO Board Stand GB 33544. Our quality management system includes raw materials inspection, in-Process Quality Control, board appearance inspection and lab testing of very batch. We follow strict QA system to ensure consistently made, qualified boards are shipped every time. We work hard to improve our production methods.

Recommended ProductsCompany Profile

It takes 4 weeks to get the MGO cement products fully cured.The cement products can still go curing in the containers if we ship them less than 4 weeks, but the curing condition on the ocean is not under control, which will effect the quality of the products. We strongly suggest you take the curing time into consideration when you place orders.

2.Can you make products as per our requests?

Of course, we accept OEM/ODM

3.What is your packaging?

Plywood plywood / or solid wood pallet

4.What is your payment term?

We arrange the production upon receiving your deposit by T/T. By TT or LC.

5.How about the samples?

Free samples with shipping cost.